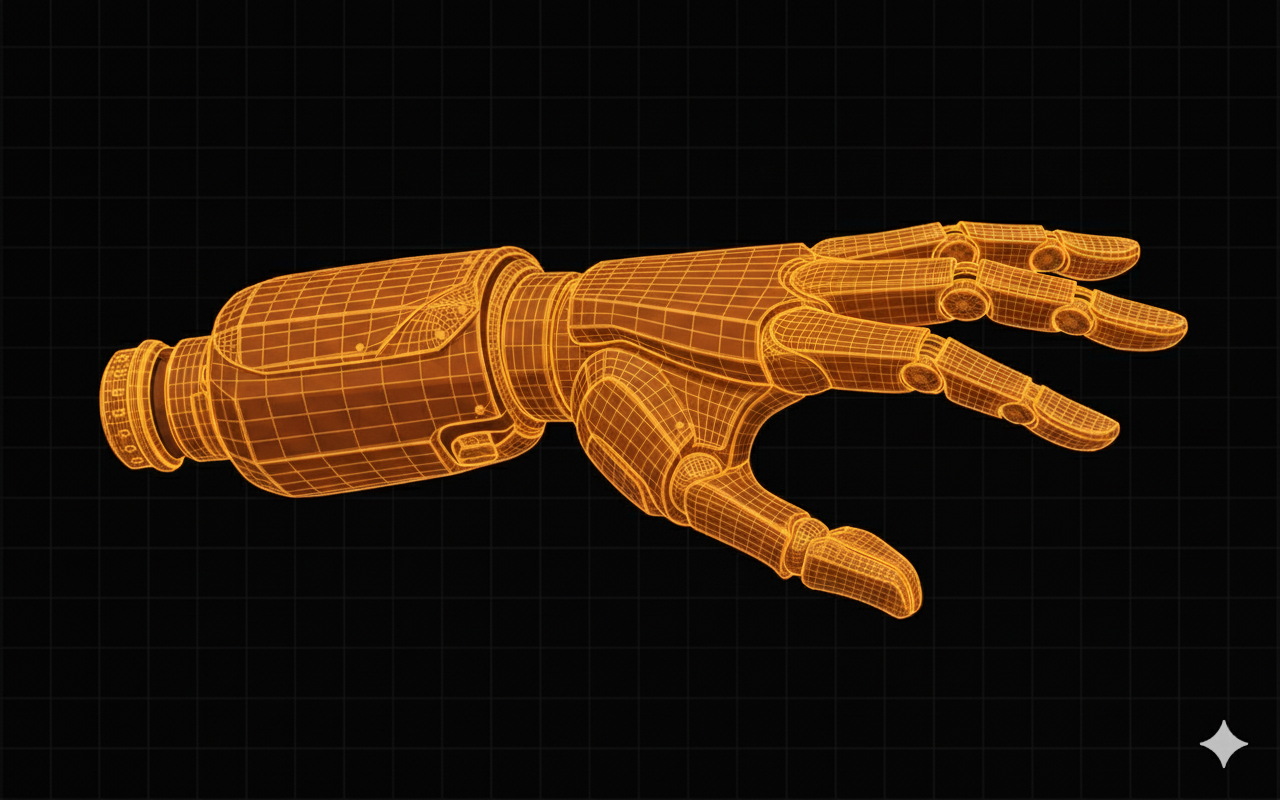

A Foundational Model for Articulated Dexterity Welcome to Mirror Hand Robotics Industries

An investigation into creating high-fidelity kinematic models of human hand dexterity for integration with general-purpose robotic platforms and large reasoning models.

Research Abstract

Modeling Human Dexterity for Robotic Systems

The objective of the Mirror Hand Robotics Industries (MHRI) project is to deconstruct the kinematic and dynamic complexity of human hand manipulation to construct a foundational model of articulated dexterity. This research posits that by mirroring biological motion, robotic systems can achieve a significant leap in manipulative capability. The MHRI acronym is also representative of the project's focus on **M**ultimodal **H**uman-**R**obotic **I**nterfaces.

Our approach utilizes commercially available robotic components and advanced data capture techniques—including motion capture gloves and video analysis—to build a comprehensive corpus of human hand movements. This data informs a universal "dexterity engine" designed for integration with diverse robotic platforms and AI reasoning models, aiming to unlock new potentials in automation and human-assistive technologies.

Methodology

A Three-Phase Approach

1. Data Corpus Development

A multi-modal data acquisition strategy is employed to capture high-fidelity hand motion. This includes data from haptic and motion capture gloves, alongside extensive video analysis of subjects performing a spectrum of complex manipulative tasks.

2. Kinematic & Dynamic Modeling

The aggregated data corpus is processed through machine learning frameworks to construct a detailed digital twin of human hand capabilities, modeling kinematic chains, force application, grip typologies, and fine-motor coordination.

3. Platform Agnostic Integration

The resulting models are engineered for broad compatibility, enabling deployment on diverse hardware platforms and integration with large reasoning models (LRMs) via standardized APIs.

Domains of Application

Potential Areas for Further Research

Advanced Manufacturing

Automation of intricate assembly, quality control, and delicate material handling tasks.

Teleoperation

High-fidelity remote manipulation for applications in surgery, hazardous material disposal, and exploration.

Assistive Robotics

Development of sophisticated prosthetics and assistive robots with near-human grasping and manipulation capabilities.

Experimental Sciences

Enabling robotic platforms to perform delicate laboratory procedures with high precision and repeatability.